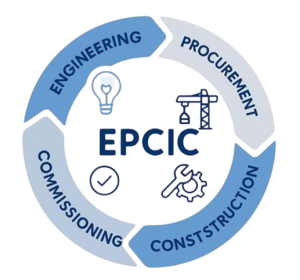

EPCIC (Engineering, Procurement, Construction, Installation, and Commissioning)

Engineering

Engineering design

- Preparation of architectural and structural designs, Electrical, mechanical and sanitary works for the project.

- Determine the technical specifications of the equipment and materials to be used in the project.

Technical studies

- Conducting the necessary studies such as soil studies, environmental studies, and technical feasibility studies to ensure the project’s compatibility with the local environment and technical specifications.

Preparing detailed plans

- Detailed engineering drawings of all elements in the project such as piping, foundations, electrical, mechanical, heating and cooling systems.

Technical feasibility analysis

- Ensure that the design is consistent with the project's operational objectives and cost and time requirements.

The Goal

Ensuring that the project is carefully planned so that it can be successfully implemented in later stages.

Procurement

At this stage, all materials and equipment that will be used in the project are purchased. The following activities are included:

Purchase of materials and equipment

- Determine the required materials and equipment based on the engineering design. This includes all materials such as iron, cement, pipes, electrical appliances, machines, equipment, machinery, generators, etc.

Selecting suppliers

- Negotiating with suppliers to select the best offers in terms of cost and quality. This may require requesting technical and price quotations and conducting technical and price comparisons between suppliers.

Supply Chain Management

- Coordinate the purchasing process to ensure materials arrive on site on time without delay.

Quality control

- Ensure that the supplied materials meet the required specifications and comply with quality standards.

The Goal

Providing all required materials and equipment with the highest quality and best cost in a timely manner.

Construction

Actual work begins at this stage on the ground, and includes the following activities:

Construction works

- Carrying out basic construction works such as excavation, foundation construction, and concrete pouring.

Building and structures

- Construction of infrastructure, including roofs, walls, and other facilities.

Monitoring and follow-up

- Monitor the progress of work to ensure that it is proceeding according to the specified schedule.

- Ensure that all works are carried out in accordance with approved engineering designs.

Dealing with field challenges

- Address any issues that may arise during implementation such as soil changes or weather challenges.

The Goal

Building the foundations and basic structures of the project according to the approved plans.

Installation

This phase includes the installation of all purchased equipment and devices. Activities include:

Equipment installation:

- Installation of machinery, electrical systems, mechanical systems, and other special systems such as air conditioning systems or security systems.

Mechanical and electrical installation

- Installation of pipes, electrical wiring, electronics, and other specialized equipment.

Installation tests

- Ensure systems are properly installed. Initial tests are performed on equipment and systems to ensure they are ready for use.

The Goal

Ensure that all equipment is properly installed in accordance with technical specifications.

Commissioning

This is the final stage that involves testing all systems and ensuring the project is working efficiently. Activities include:

Final exams

- Conduct comprehensive tests on all installed systems and equipment such as electrical tests, mechanical tests, and operational tests.

Ensure efficiency

- Ensuring that systems and equipment are operating properly and efficiently. This includes ensuring that there are no problems that could affect performance.

Training

- Training of personnel on how to operate and maintain the system. Training may include operating equipment, understanding processes, and performing preventive maintenance.

Delivery

- Officially hand over the project to the client, after ensuring that everything is working as planned.

The Goal

Ensuring that the project is ready to operate, that all systems are operating at high efficiency and that operations can be officially started.

Why use EPCIC model

Integration of activities

Greater control over time and cost

Reduce risk

EPCIC is a common model in large and complex projects such as oil and petrochemical projects, major engineering projects.

Power stations, industrial projects (factories), modern projects (hospitals, universities, etc.) require precise coordination between all participating parties to ensure the success of the project and achieve the desired goals.

EPCIC model is used in turn-key projects as well.